Bellanca Heritage

Excerpts from Delaware Public Media

Giuseppe M Bellanca was born in Sicily Italy in 1886. He spent his early adult years in Italy designing and building airplanes. Many years later, and after many accomplishments and notoriety in aircraft design and the urging of Henry B. du Pont placed him in New Castle Delaware his ultimate aviation destination with the forming of the Bellanca Aircraft Corporation. He originally arrived in the U.S in 1911 and approximately one year later in Brooklyn New York built his first single engine airplane. This was a revolutionary new design from that of what the Wright Brothers and other early designers had followed which had always positioned the horizontal and vertical structurers (now considered the tail) in the front of the airplane and the propellor in the rear (a pusher configuration) The new Bellanca design provided for a high wing placement. the propellor in the front and the tail and vertical stabilizer in the rear.

Giuseppe Bellanca taught himself to fly in this airplane in Long Island New York in 2012. Once he had learned to fly he began teaching others from 1912 to 1916 with his new Bellanca Flying School. He taught Fiorello LaGuardia to fly who later became the mayor of New York City. He later joined the Wright Aeronautical Corporation developing many designs, the WB-1 and WB-2 aircraft that won air races around the world. In 1926 Bellanca left Wright and partnered with Charles Levine to form the Columbia Aircraft Company of New York. They would now rename Bellanca`s well proven design the WB-2 the Columbia.

CHARLES LINDBERG – HIS FIRST CHOICE TO FLY THE ATLANTIC – THE BELLANCA COLUMBIA

In the movie LINDBERGH (still shown at this time) and played by Jimmy Stewart, in one of the opening scenes portrays Stewart (LINDBERGH) in pursuit as his first choice to fly the Bellanca Columbia across the Atlantic. The Bellanca home office (at that time) was located in a tall skyscraper building at the southeastern tip of Manhattan Island. This included quick access to Bellanca`s Sea Plane Base docking facility on the lower East River which also housed their company seaplane. However It was also the intention of Levine for their Bellanca Columbia to be the first to cross the Atlantic with their own pilot which they were preparing to do. There was a $ 25,000 prize. Bellanca with Levine`s influence declined Lindberg`s request as they were in the race with expectations that their own company pilot flying the Bellanca Columbia model would prevail against all others. Lindbergh then chose and flew the Ryan NYP, The Spirit of St. Louis to Paris in April of 2027 winning the prize. Unbeknownst to many, the Bellanca successfully crossed the Atlantic about two weeks later with their pilot going even further non stop all of the way to Eisleben, Germany in 43 hours. So much for second place. Bellanca himself somewhat disappointed with Levine and the Columbia not being the first to accomplish the New York to Paris flight ended his relationship soon after with Levine.

In 1928 at the urging of Henry B. du Pont Giuseppe Bellanca established the Bellanca Aircraft Corporation. The Columbia then evolved into the CH series, which was used in numerous and famous record setting flights. One of the most notable was the Miss Veedol, flown in 1931 on the FIRST NONSTOP FLIGHT ACROSS THE PACIFIC from Japan to Wenatchee, Washington. Through the 1930`s, many new and larger models were developed by Bellanca and with their excellent reputation as being efficient and reliable were purchased by governments, businesses, celebrities as well as airlines in South America, Central America, Asia and Europe.

Bellanca Aviation built more than 3000 airplanes in New castle Deleware during World War II and employed over 3000 workers. After many successful decades Giuseppe Bellanca sold the business in 1954 and retired to Galena Maryland. He died in 1960.

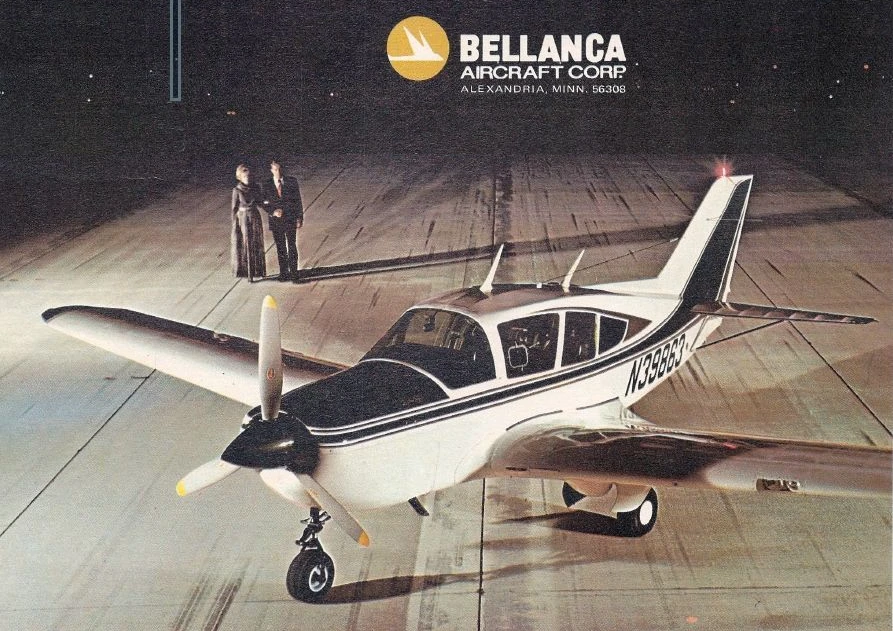

PRIOR TO HIS RETIREMENT the 14-13 series single engine Bellanca was designed which later became the 14-19-2, the 1419-3, the 260B with a larger engine and ultimately the Bellanca Viking 300 and the Bellanca Super Viking. These aircraft were manufactured from 1956 forward on the Alexandria Minnesota municipal airport in a new 56,000 square foot aircraft manufacturing facility becoming a sizable publicly stock traded company. In 1980 Bellanca Incorporated formed as the new company and in 1987 Mike Pinckney purchased all of the Bellanca Inc. assets and stock and continued to manufacture the Bellanca Super Viking in Alexandria Minnesota over the next fourteen years. There were significant performance related improvements as well cosmetic upgrades in the Super Viking throughout his ownership including additional speed and the upgrading to the Teledyne Continental IO-550 engine.

The 1419 Series Ultimately Developed Into The Bellanca Super Viking

The 14-13 and 14-19 series ultimately developed into the Bellanca Super Viking in 1967 and was designated "plane of the year" by "Plane and Pilot" magazine. It`s long term heritage however, dates back to the 1920’s, and furthermore, to 1912, with Giuseppe Bellanca’s first design.

The Bellanca name, the oldest marque in American general aviation, since its inception has always been associated with the finest craftsmanship and attention to detail. In a Bellanca Viking you are surrounded by a protective heavy tubular steel roll cage to better protect you which is unmatched in strength and total protection by other airframe manufacturers. The ingenious design of the wing still outperforms most others in its class to this day. The roll rate of approximately 90 degrees per second is achieved while maintaining extreme stability in all three axes of flight, including stall configuration and slow flight through maximum cruise, the mark of excellence in aeronautical engineering. Often one or two axes of extreme performance are achieved at the expense of other flight characteristics.

The Super Viking is now an accumulation of nearly a century of knowledge, expertise and refinement. All of this is incorporated into the final product which competes and performs at the very highest level with all competitors, all the while exhibiting a mixture of modern design and engineering, and maintaining its well-established heritage. The 210 MPH cruise speed is competitive and the quality of the airplane well exceeds that of most aircraft in its category. Often referred to as a true modern classic, the continued following of Bellanca through the years has been attributed to the willingness of the company to change where true advantages can be gained, while maintaining the commitment to retain the Super Viking’s proven superior design.

MATERIALS UTILIZED - MANUFACTURING

Over the years the philosophy of Bellanca has always been to incorporate the finest materials available as applicable to their purpose. For this reason you will find, by design, the assembly of many different materials in each aircraft. The design and manufacturing process is not duplicated by any other in the industry. The construction process, sometimes considered labor intensive and old fashioned, requires total personal craftsmanship at every level. The integrity is evident in the finished product. Bellanca heritage has for almost a century now produced the very finest in aviation products through its continued refinement in design, engineering and commitment in providing the very highest level of quality , detail and craftsmanship.

The exterior design of the Super Viking consists of Dacron, aluminum, steel and fiberglass. Dacron is virtually everlasting and has received a lifetime rating by the FAA eliminating the repetitive requirements of annual puncture testing. Cared for properly and undamaged, it is likely you will never have to recover your Bellanca Super Viking. In fact you should pay extra attention if you are considering the purchase of one that has been recovered and the reason for it. After almost 45 years of use on the Super Viking, the integrity of the Dacron on the first Vikings manufactured have in most cases remained ageless. Unbeknownst to many, there are numerous advantages to the application of Dacron over mahogany and 4130 steel alloy tubing as opposed to the full monocoque design. In fact, Dacron is superior even to full composites in many ways. It is lighter, more flexible and absorbent to abrasions and stresses which often result in damage to other surfaces. Dacron will not dent and IS NOT VULNERABLE TO CORROSION AND CRACKING. It is relatively inexpensive to spot repair in comparison to that of other structures. Damage occurs only in forceful mishaps. The factory craftsmen are available for repairs should a mishap occur.

YOU ARE SURROUNDED BY A TUBULAR STEEL FUSELAGE. IT IS EXCEPTIONALLY STRONG AND PROVIDES THE PROTECTION OF A ROLL CAGE. The fuselage consists of military specification 4130 Chrome-Molybdenum steel tubing. The numeral depicts the alloy specification. The diameter and wall thickness however are varied throughout the airframe. The frame surrounding the cabin section of the fuselage, for example, is 1 ¼” diameter by .049 wall thickness. The strength of the remaining fuselage design far exceeds the requirements of handling the induced loads which will be experienced in its certification category. It is often referred to as overbuilt to the extreme in all structural areas.

BELLANCA HAS NOT HAD THE PHILOSOPHY THAT ALUMINUM IS NOT AN EXCELLENT PRODUCT. Aluminum is a superior product for selected design applications. In these areas Bellanca has utilized aluminum where it has evidential superiority. The fuel cells, firewall block, elevator trim tab, rudder trim, instrument panel, cowl flaps, inspection covers, access plates, fairing straps, other attachments, other miscellaneous items, and spinner are all constructed of aluminum. An aluminum skin also wraps around the forward section of the cabin and windscreen. The three doors enclosing the nose wheel are aluminum. FIBERGLASS is utilized to construct both the upper and lower cowlings, the cabin and baggage doors, the main wheel doors, taxi and landing light housings, wing root fairings, interior glare shields, window frames, the dorsal fin area and the ski tube, along with other select applications.

INTERIORS: Interior design and quality has been one of Bellanca’s definitive trademarks for over a half century. Interiors are hand stitched from luxury leathers, fabrics and vinyls of the very highest quality and most feel, the finest in the industry.

WINGS: RESPECTED IN THE INDUSTRY FOR OVER SIXTY YEARS. The legendary wing designed by Giuseppe Bellanca has received praise from the most renowned engineers in the industry for over sixty years. The wings of the Super Viking are constructed of mahogany, birch and the finest Sitka Spruce available, which is used to manufacture the spars and ribs. In today’s modern world of composites few understand these are actually nature’s very finest and virtually everlasting composite when properly protected. Additional wing strength is derived from the use of large quantities of small pieces laminated together (over 1,800 pieces per wing), engineered and designed to provide maximum strength. The internal structure of the wings is enveloped in 1/8 inch mahogany, further strengthening the rib and spar construction. The finest sealer is then applied to the enclosed wing structure. This is accomplished by mounting the wing structure in a specifically designed jig, filling with the preservative and rotating 360 degrees in all axis to ensure saturation of all interior surface wood fibers. Upon completion of this process Dacron is applied to all exterior surfaces and finished through 17 crosscoats (34 layers) of a build up process which not only protects, it provides a final finish which creates a GLASS-SMOOTH AND RIVETLESS SURFACE.

There are many advantages to a spruce and mahogany wing structure other than providing superior strength. They are virtually ageless. On the occasions when Bellanca wings from the 1940s are professionally inspected on aircraft that have lead a well cared for life the wings can rarely be distinguished from those of a new Viking. Another advantage is the absorption of vibration and reduced noise level. They truly provide a more comfortable ride. These wings have no metal fatigue, corrosion, or cracking to cause loss of strength and are flexible to bend which can eliminate damage possible in metal airplanes. Additionally, the use of spruce and mahogany allows forming and shaping the wing into the precise aerodynamic design required for the desired flight characteristics.

PHILOSOPHY

Bellanca over the years, however, has not been unwilling to evaluate change. In fact an open mind has been an ongoing consideration at Bellanca. Many of the procedures outlined are the result of many improvements incorporated over the years. Philosophy has been, however, not to change for the sake of change with every emerging development in the industry as there have been many in recent years.

An example is Bellanca Inc. conducted a very expensive and extensive evaluation of the composite wing in recent years. The result was an ever-convincing conclusion that the current spruce and mahogany “composite” process was as superior a structure when all things were taken into consideration. After approximately sixty years of observing wing structure, the conclusion, as well as of those of some of the finest aeronautical engineers, concluded the materials and methods used are superior or equal to those used by other aircraft manufacturers. New technology methods are not always superior; sometimes they are just different, and sometimes they are just new. Bellanca will, however, continue to be open and evaluate new technology.

MAINTENANCE

The Bellanca is a complex airplane to manufacture however, once it is built, it is well done. Properly cared for and maintained, there is little to malfunction. It is simple for any competent A&P service personnel to understand and service. Technical assistance is in most cases available with a simple phone call to the factory. The company provides technical support to existing Bellanca owners. Additionally, almost any part you will ever need is available.

PERFORMANCE

A test flight in the Super Viking is essential to fully understand and appreciate its flight characteristics and performance capabilities.

SUMMARY

THE BELLANCA SUPER VIKING provides for a unique and enjoyable ownership experience, inexpensive to maintain, and the performance figures are in most cases consistent with or exceed those of most modern day high performance single engine aircraft. The Bellanca is generally more suited for those who value performance, luxury, utility, safety, and comfort. Most purchasers possess an appetite for a certain uniqueness and have a great appreciation for their craftsmanship. A limited production schedule has always enabled a high level quality control standard built into each aircraft. If you appreciate the finer things in life as well as one of the finest values in aviation, you may want to consider a Bellanca Super Viking if you find yourself in the market for a high-performance single engine airplane. It has been said of the Bellanca Super Viking for almost fifty years now "Nothing in its class has its class."

Copyright 2006-2024 Pinckney Aircraft

All rights reserved

(Photographs)

Please contact Pinckney Aircraft to request use